1) The surface of the adhesive corner code is seamless, with good sealing performance to prevent corner leakage;

2) Overall beautiful appearance;

However, at the same time, seamless welding also has very obvious drawbacks:

1) Insufficient resistance to pressure, as shown in the video, 682 Newtons of force is sufficient to cause damage to the horn assembly; The force of 682 cows is equivalent to 70kg, which is about the weight of an adult man

2) Over time, cracks are prone to occur, such as surface forming cracks, transverse cracks, solidification cracks, segregation cracks, cracks under the weld bead, and cracks at the center of the weld bead. And the reasons for these are related to low melting point elements. Because it is seamlessly welded as a whole, once cracks appear, the entire window can only be replaced.

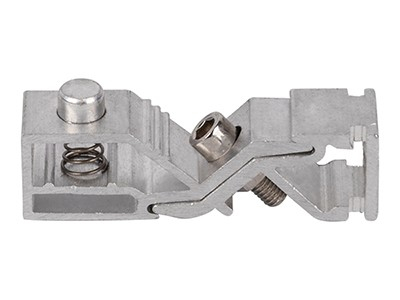

Let's take a look at the glue injection process for corner code pins. Similarly, the two ends are cut into 45 ° profiles for splicing. Before splicing, professional waterproof sealant (also known as section anti-seepage adhesive) used for doors, windows, and curtain wall structures is applied to the section. During assembly, corner codes with nail polish material are used for splicing (nail polish material has the advantage of strong toughness).