For those in the door and window industry, corner connectors are very familiar door and window accessories. However, for ordinary consumers, they may not even be aware of its existence. In a finished window, we can neither see nor touch it. The role of corner connectors in doors and windows is quite significant. It is no exaggeration to say that corner connectors largely determine the performance and service life of doors and windows.

There are many types of corner brackets: in terms of usage scenarios, they are divided into frame corner brackets and middle post corner brackets. (The corner brackets for glass sashes and screen sashes are essentially the same as those for frames, and are all used in right - angle splicing.)

What is an integrated angle code?

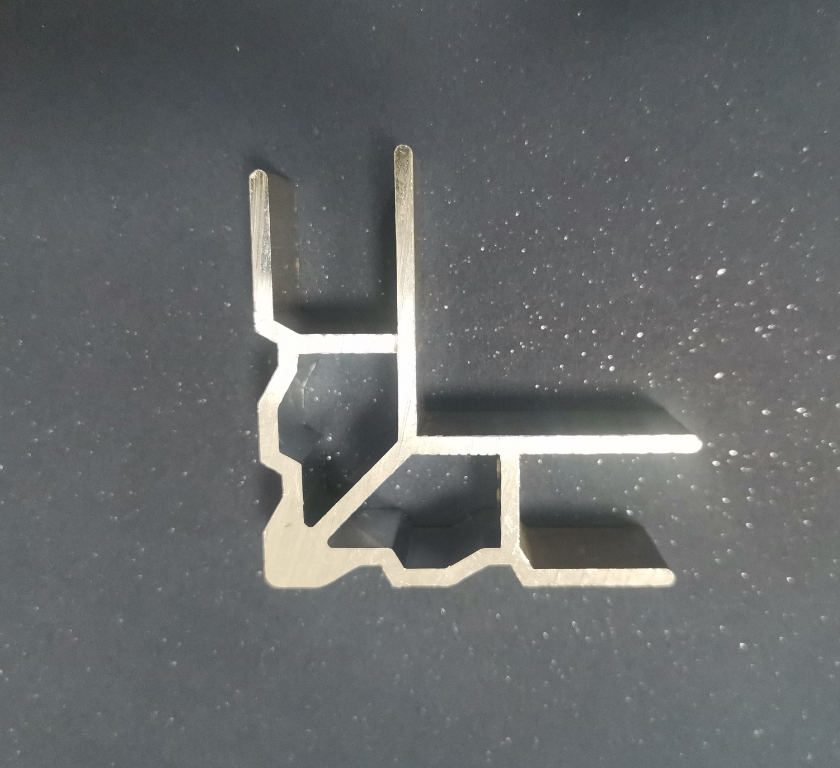

Integrated angle code

Integral corner code, also known as overall corner code. As the name implies, it is a whole. If further subdivided, it can be divided into impact corner code and dowel corner code.

The corner codes of the battering ram are a bit troublesome to process and require a special corner joining machine. The assembly needs to be completed in the workshop and cannot be done on-site. If the window size is too large to be carried up the stairs, hoisting equipment must be used.

Second, when the corner - squeezing knives of the corner - squeezing machine penetrate the surface of the aluminum profile, due to the inconsistent resistance strength of the aluminum profile encountered by the two corner - squeezing knives during the penetration process and the inability to maintain a consistent penetration progress, and the inability to restrict the destructive stress of the corner - squeezing knives on the aluminum profile, the local shape of the aluminum profile is distorted, affecting the corner - assembling quality.

In addition, if misalignment is found after the corner assembly is completed, it cannot be adjusted.

Because of its high processing efficiency and relatively low cost, it is currently one of the most commonly used corner connectors.

Horn angle code

Corner assembling machine

Pin corner connectors are fixed with pins. Its advantage is that it can be assembled on - site without the need for professional equipment. This type of corner connector is the most widely used at present.

Pin corner joint

Later, there was also an upgraded version that integrated these two functions into one corner code. It can be used for both corner bumping and fixing with dowels.

Battering ram pin corner fitting

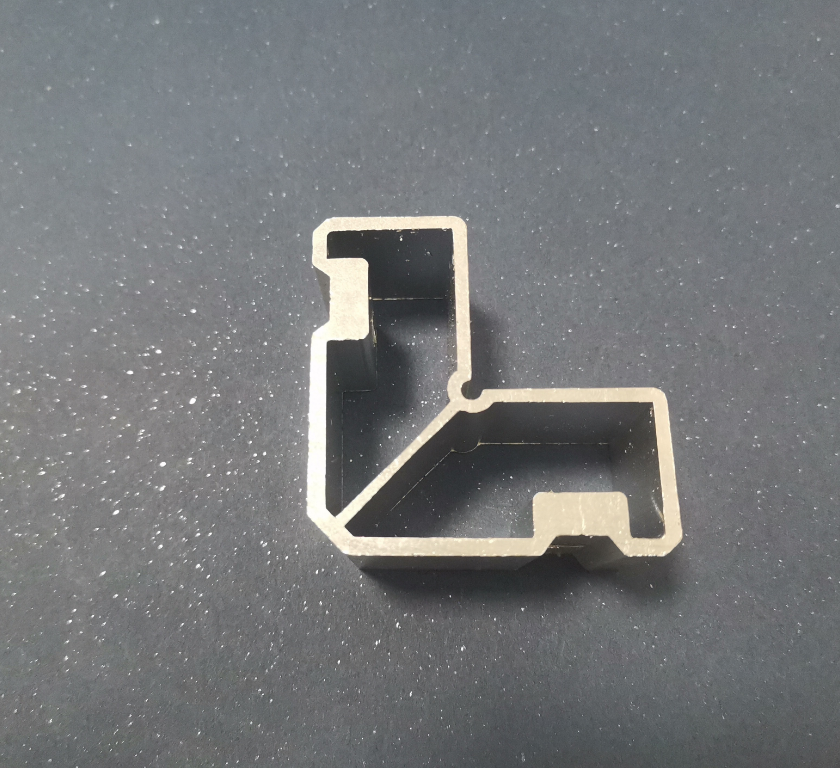

Activity corner code

Compared with the integral corner code, the movable corner code is composed of two components connected by high-strength bolts. It does not damage the chamber of the aluminum profile (the external dimensions will not be distorted), avoiding the problem of the fourth corner offset. The greatest advantage is that when there is a misalignment in corner assembly, it can be loosened, readjusted, and then tightened again. This is something that ordinary impact corner codes cannot compare with. Compared with the integral corner code, the movable corner code is more complex to process and has a higher cost.

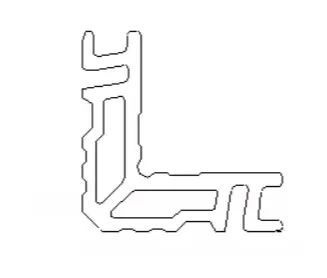

Expansion angle code

Simply put, it means sawing the one-piece corner bracket longitudinally, drilling holes, and then using screws to expand it to achieve a stable effect.

Expansion angle code

This kind of corner fitting can not only be installed on - site, but also has an advantage of self - leveling and high efficiency.

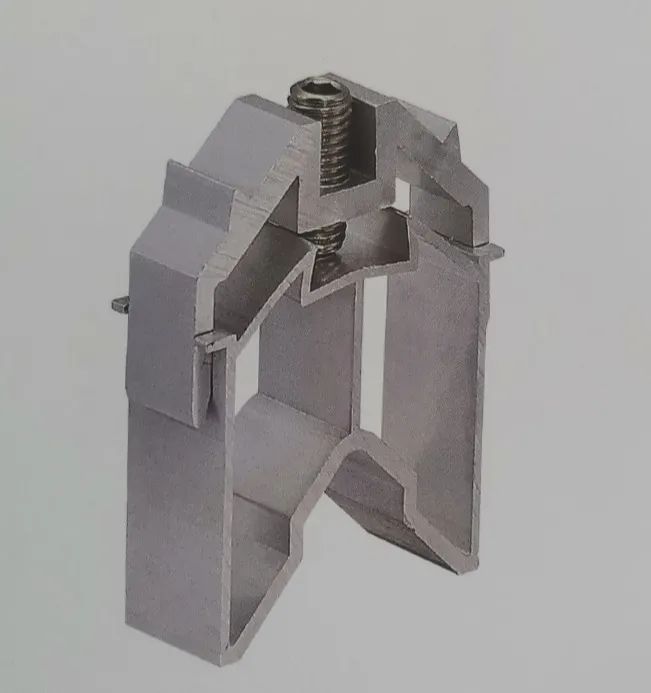

Raise the subscript

Open a screw hole at 90 degrees. Then, while tightening, the two materials will separate, and the sharp corner on top will pierce into the profile, thus fixing it. The cost is relatively high, and it is more commonly used in high - end doors and windows.

Injected glue corner code

Strictly speaking, the glued corner connector is not a category, but only a functional improvement. The above-mentioned types of corner connectors can all be made into glued corner connectors. After connecting the corner connector to the profile, glue is injected to improve the firmness and tightness of the doors and windows.

Integral glued corner connector, dowel glued corner connector, expansion glued corner connector.

PART2

Middle column corner code

The angle codes used at the joint of the middle column and the frame.

Thimble angle code

While the above screw is being tightened, the thimble will pierce down into the profile, thus fixing it.

Universal middle column corner code

This kind of subscript is highly versatile.

Corner codes for the activity center column

Each kind of corner code comes in a great many sizes. Despite their small size, corner codes hold great significance. Our company currently has nearly 150 types of corner code profiles.