Several factors affecting the reliability of corner assembly with aluminum corner codes

Selection of profiles

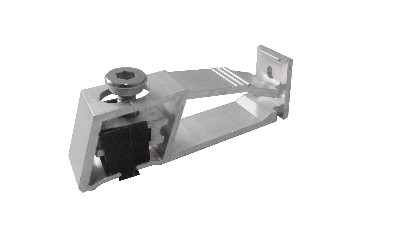

The wall thickness of the profile has an equally important impact on the reliability of corner assembly. As for the corner assembly process alone, because the aluminum corner code connection is achieved through the deformation of the profile, the wall thickness of the profile directly affects the strength of the connection.

The cavity structure of the main profile should strive for rationality. The profiles used for aluminum alloy doors and windows are thin-walled parts. If there are errors between profiles, it is easy to cause the corner assembly process to be too complicated or the corner assembly to fail.

The accuracy of processing equipment and the cutting accuracy of profiles affect their processing accuracy, which in turn affects the reliability of corner assembly. In other words, the accuracy of processing equipment is one of the main factors affecting the corner assembly effect.

Before operating the aluminum corner code, it is necessary to check whether the corner machine is operating normally, adjust the pressure, and only start working when the air pressure meets the requirements.

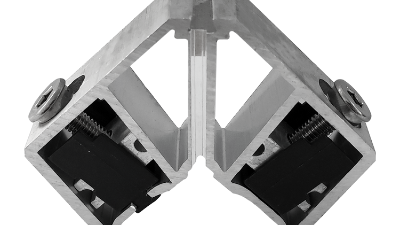

Select molds that match or match the profile section according to the production work order and drawing requirements, and the accuracy of the molds should be within the allowable range.

Determine the positioning surface and clamping surface according to the process design requirements and profile section, adjust the matching dimensions, and conduct an empty vehicle operation test to ensure the synchronization and consistency of each group of corner cutters.

The positioning must be accurate, and the dirt on the table should be cleaned in a timely manner to avoid affecting the surface of the profile and causing defects that are difficult to recover.

The semi-finished products after corner assembly should be neatly stacked and left to stand for six hours before waiting for the corner adhesive to completely dry before proceeding to the next step of processing.