Aluminum corner codes play an indispensable role in the manufacturing of doors and windows. It is a hardware component that connects doors and windows at a 90 degree right angle intersection. Corner codes are generally used in decorative engineering and furniture assembly, and are made of materials such as aluminum, glue, zinc, etc. Aluminum alloy doors and windows mainly use aluminum corner brackets, which have good thermal shrinkage, hardness, and other properties. Pure aluminum corner brackets have better stability compared to corner brackets made of other materials.

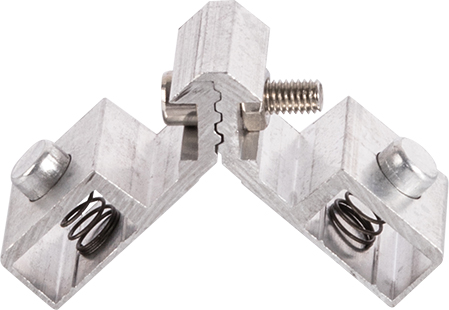

Activity aluminum corner code: It is composed of two aluminum pieces, connected by screws in the middle, and comes with a locator, making it easy and convenient to use. After binding the aluminum alloy corner codes, the neatness of the corner seams can be improved, which can extend the service life of doors and windows. The disadvantage is that over time, the sealing, sound insulation, and wind pressure resistance of the window may decrease. This type of corner code is generally used by small door and window manufacturers, and is used by a small number of products from brand manufacturers.

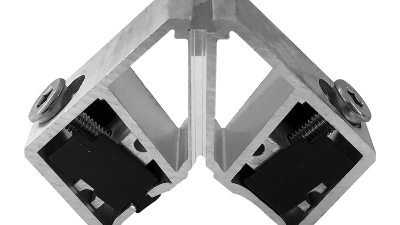

Glued aluminum corner code: It is a commonly used door and window corner code by brand manufacturers, made of cast aluminum injection, with improved overall strength and aesthetic appearance of corner joints. And there is a guide groove inside, which can be glued after assembly. The glue will fill the corner code through the guide groove to expand the two corner codes outward, making the assembly more compact. The sealing and waterproof properties have been enhanced.