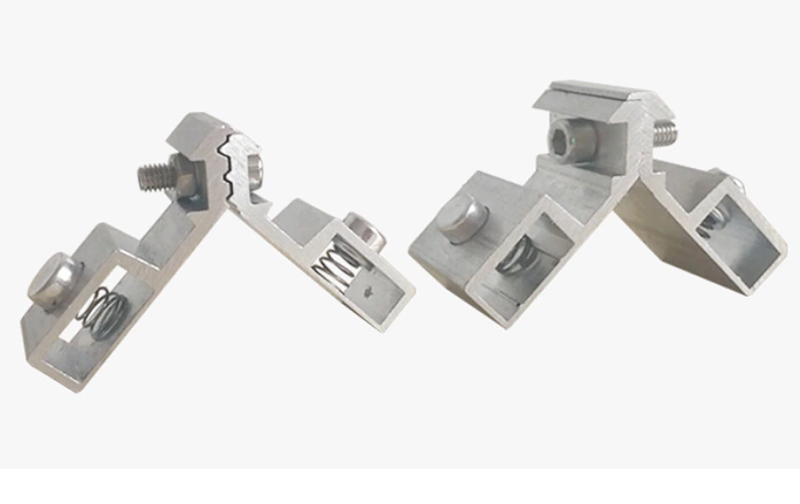

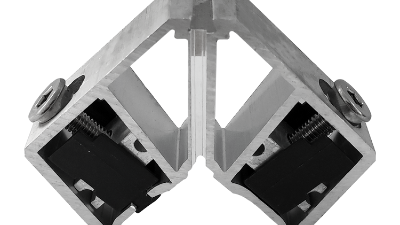

The corner connectors (movable corner codes) are connected by high-strength connecting bolts, and compared with the method of using an angle squeezing machine, the movable corner codes do not damage the cavity of the aluminum profile (the external dimensions will not be twisted to avoid the problem of the fourth corner offset). Each worker can assemble 15-25 frames per hour.

The corner connector (movable corner code) has undergone an "L" - shaped single angle force test (up to 35000 Newtons or more), which is more than 20 times larger than the extruded corner code (about 1800-2000 Newtons). (Due to the unreasonable connection structure of the extruded corner code, when external pressure is applied to the test angle during corner strength testing, the extruded outer skin of the aluminum alloy profile is gradually flattened and detached from the corner code. However, due to the reasonable connection structure, the pressure is directly transmitted to the movable corner code itself during testing until the test angle is completely destroyed.).

The advantage of the activity corner code is that when there is a misalignment in the corner assembly, it can be loosened and readjusted again, which is incomparable to ordinary corner codes! The movable corner code can achieve on-site assembly of doors and windows. Aluminum alloy door and window factories in Europe can do door and window projects in Asia relying on this characteristic of the movable corner code to ensure safety. After receiving the order, the factory cuts the aluminum alloy profile and punches out the installation hole of the movable corner code, directly boxes it, and ships it to the site for assembly with the movable corner code, door and window hardware, etc

Profile cost: Due to the simple principle of connecting with movable corner codes, the strength of their corners is achieved through structural means, with a small amount of aluminum used and a small profile chamber requirement (thickness of 14 millimeters). Compared with traditional extruded corner codes (thickness of about 20 millimeters), using movable corner codes for profile standard windows can save 10% to 15% of profile aluminum consumption