The seamless welding technology for doors and windows has been gaining popularity recently, with many businesses using it as a selling point and praising the seamless welding process. So what exactly is the seamless welding process? What is the difference between the adhesive corner code assembly process and the conventional system doors and windows?

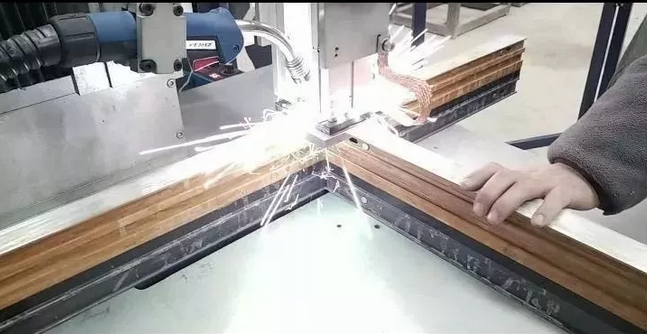

Seamless welding may sound fancy, but it's also easy to explain. Aluminum alloy window sashes are assembled from aluminum alloy on four sides. The outer joint interfaces of the four sides are welded and polished, and then the welded window sashes are sprayed on the surface to achieve "seamless welding", more precisely, seamless welding on the surface.

The welding method is obvious and looks good. There is only one point where the main parameters such as air tightness, water tightness, and window strength have not been significantly improved. On the contrary, after such a round of welding and polishing, the stability of the window may be compromised, which is not worth the loss.

The aluminum profiles used for doors and windows are 6063~T5 profiles, which are not suitable for welding. Secondly, the strength of the weld seam of aluminum alloy will change after high temperature, and then it will be polished flat, making the profile of the weld seam where the strength has already decreased thinner, and the stable strength of the window can be imagined compared to before.

The door and window profiles are cavity structures, and the main stress location is the joint of the side fittings. They cannot be welded internally, which cannot guarantee the balance of structural stress. The important insulation for aluminum alloy doors and windows is the insulation strip (commonly known as the broken bridge), which is made of melamine glass fiber. The seamless welding production process is opposite to the conventional corner assembly process, which involves welding and polishing before spraying. The normal spraying temperature in China is above 200 degrees Celsius, and the temperature is difficult to control. After withstanding a high temperature of 200 degrees Celsius, the strength and performance of the insulation strip will be affected.

Once the window is subjected to micro vibrations, temperature changes, environmental weathering, and other factors that cause weld seam rupture, the air tightness, water tightness, and insulation performance of the window will sharply decrease.

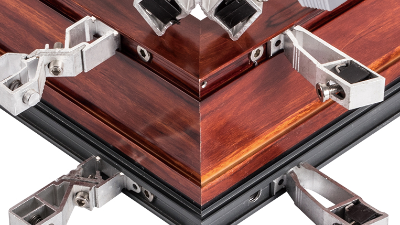

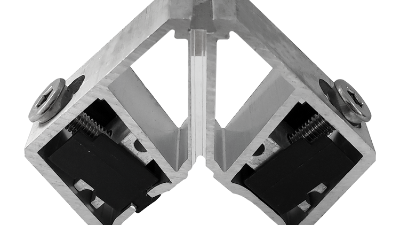

The process of using adhesive corner codes to assemble corners is also very simple. The four connection corners of the aluminum alloy window sash are connected by mechanical corner assembly, and special corner adhesive is injected into the window with high pressure. Specialized corner adhesive has high bonding strength, strong temperature resistance, good weather resistance, and low elasticity after curing, which enables flexible connection between corner brackets and profiles, effectively solving many problems such as window corner cracking, misalignment, deformation, and leakage. It achieves a tight and consistent window.