The characteristics of aluminum corner codes are material stability, strong weather resistance, resistance to deformation, and long service life. In terms of waterproofing and sound insulation, the effect is more significant.

1. Installation with base plate: Adjust the verticality and levelness, apply white latex on the back of the door frame main board, and use straight gun nails or self tapping screws to directly fix it on the door opening base plate;

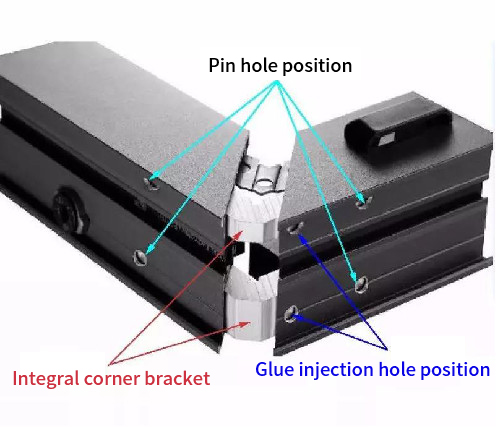

2. Installation with foam adhesive: Place the door frame main board inside the door opening, adjust the verticality and levelness, use self tapping screws to match the gasket or aluminum corner code for positioning, and use suitable support rods at the bottom and middle of the door frame main board (to prevent deformation when the foam adhesive expands), and then fill and fix it with foam adhesive;

3. Installation with aluminum corner codes or screws: Place the door frame main board inside the door opening, adjust the verticality and levelness, and use self tapping screws to match the cushion plate or aluminum corner code to directly fix it to the wall.

High antioxidant capacity and better compatibility. Aluminum corner codes have low cost and shorten processing cycles. This product is widely used in the processing of aluminum alloy doors and windows, which can directly improve economic benefits for users and significantly reduce the use of aluminum materials. Play a certain role in creating an energy-saving and environmentally friendly society for the country. Aluminum corner codes have no secondary processing, saving manpower, material resources, and equipment, eliminating cutting losses and waste, and saving energy consumption.