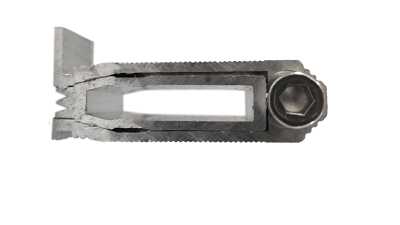

The quality of doors and windows is closely related to the processing capacity of the factory, and one important indicator is the corner joint. The connection between two profiles at the corner of a good door and window is done using aluminum corner codes. Then, the profiles are squeezed together with the aluminum corner codes using a corner forming machine, and two-component adhesive is injected into the holes to solidify the aluminum corner codes and frame materials together. Common low-quality practices include splicing without corner codes, not applying curing glue when there are corner codes, or deceiving consumers with a little bit of glue on the mouth. In addition, the quality can also be judged by touching the seam of the corner assembly with your hand, and the smoother it is, the better the quality of the corner assembly processing.

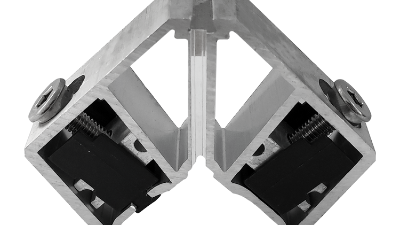

The frame and fan assembly angles of system doors and windows are generally connected at a 45 ° angle. There are at least five connection methods for 45 ° angle connections: screw splicing, rivet splicing, extruded splicing, pulled splicing, and expanded splicing. The most commonly used method currently is corner squeezing splicing, also known as collision splicing. Some are also called butt joint splicing. In order to ensure the strength and sealing of the corners of doors and windows, aluminum corner brackets are glued. An effective method is to use a special sealant designed for door and window corners, called corner sealant, to bond the aluminum corner brackets to the cavity wall of the profile, providing structural reinforcement and sealing.

As one of the very important links in the process of house decoration, doors and windows not only affect the overall visual effect, but also meet our requirements for room comfort and warmth. Doors and windows integrate various materials such as profiles, hardware, glass, and auxiliary materials. In the design, aesthetics, structural mechanics, and control of light and heat conduction, noise control, wind pressure resistance, air tightness, water tightness, ease of use, durability, and weather resistance need to be considered.